Fundamentals of Shear Testing

Though tension is the most common type of loading for material

testing, shear is also an important loading type. The behavior of

materials under shearing is important for many applications, including

forming, crash safety, and machine design. Accordingly, engineers have

created testing methods to isolate shear as the primary load so that

material shear behavior can be studied. This article will give a brief

overview of shear testing, including theory, equipment, methods,

results, and testing standards.

Relevance: Why Shear Testing?

Shear is essentially a type of loading that causes sections of

material to slide past each other. Strong shear loads are created

when two forces are applied to an object in opposite directions (we

can think of these directions as “up” and “down”) at different

locations. Resulting loads cause one section of material to deform

upward, while a neighboring section of material deforms downward.

With strong enough applied forces, the material will completely

shear apart.

Scissors are the most obvious example of shear loads at work in

everyday life. In fact, scissors are sometimes called “shears” for

this very reason! Scissors are a pair of sturdy metal blades that

almost align with each other, but not quite perfectly. When the

scissors are closed on a sheet of material, the blades push the

material in opposite directions, causing it to shear. Sharp scissor

blades aid in the shearing process, but many weak materials such as

paper can easily be cut even with blunt safety scissors. This is due

to their susceptibility to shear loads.

The relevance of shearing extends far beyond the use of scissors,

however. Any time a section of material is subject to two external

forces which are not equal and opposite, there will be shear. This

can manifest in structural beams, which experience tension, bending,

and shear forces. Many useful machine components are also designed

with shear in mind.

One example is the shear pin, which is incorporated into many types

of heavy machinery as a failsafe mechanism. If something goes wrong

during operation and the equipment experiences loads exceeding safe

limits, the shear pin is designed to fracture, disconnecting moving

parts and effectively stopping the machine. In this way, the shear

pin is sacrificed to ensure that nothing else in the machine is

damaged.

To ensure the effectiveness of components like the shear pin,

engineers must be able to predict how parts will behave under shear

loading. This is where material testing comes in.

Shear Testing Equipment

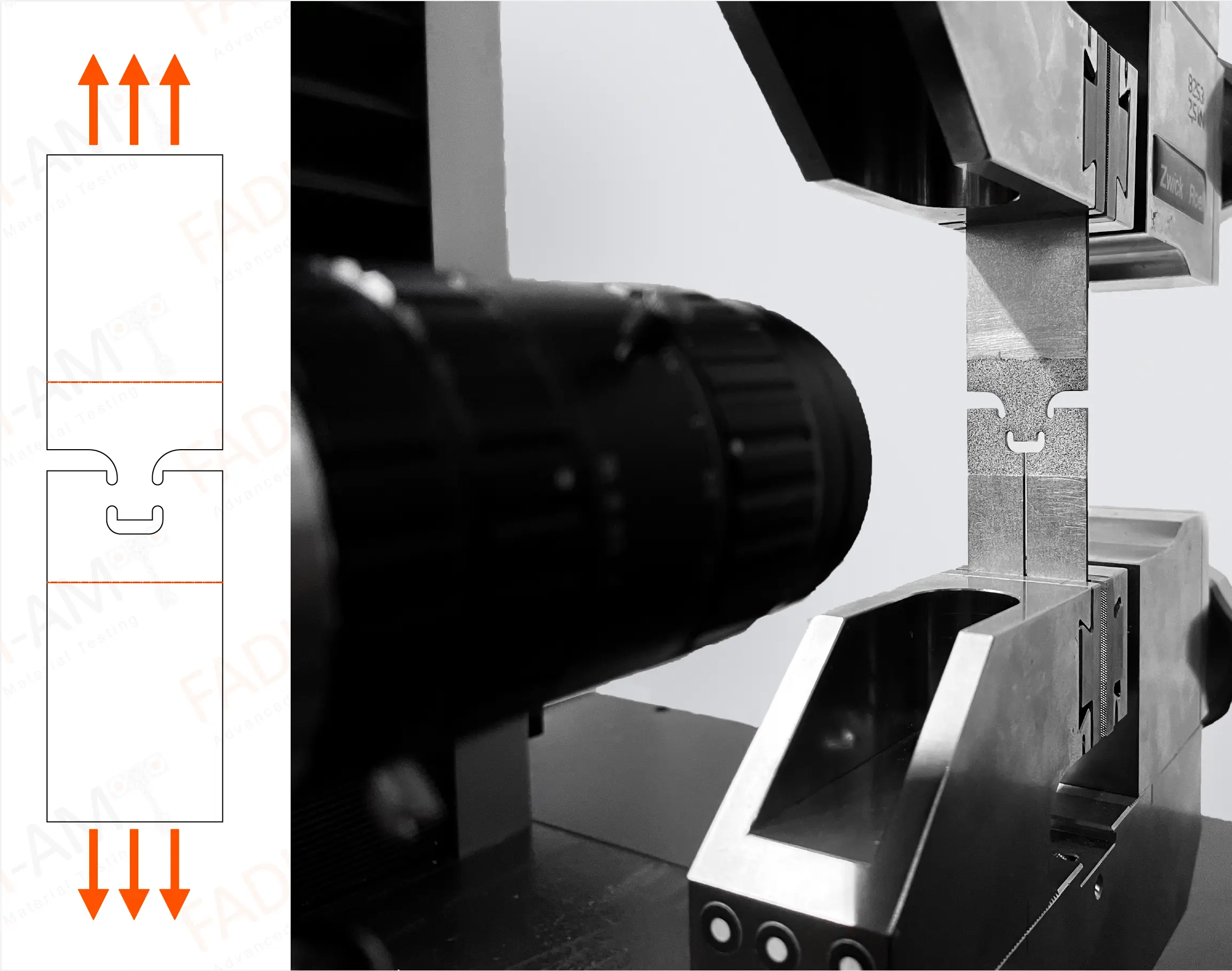

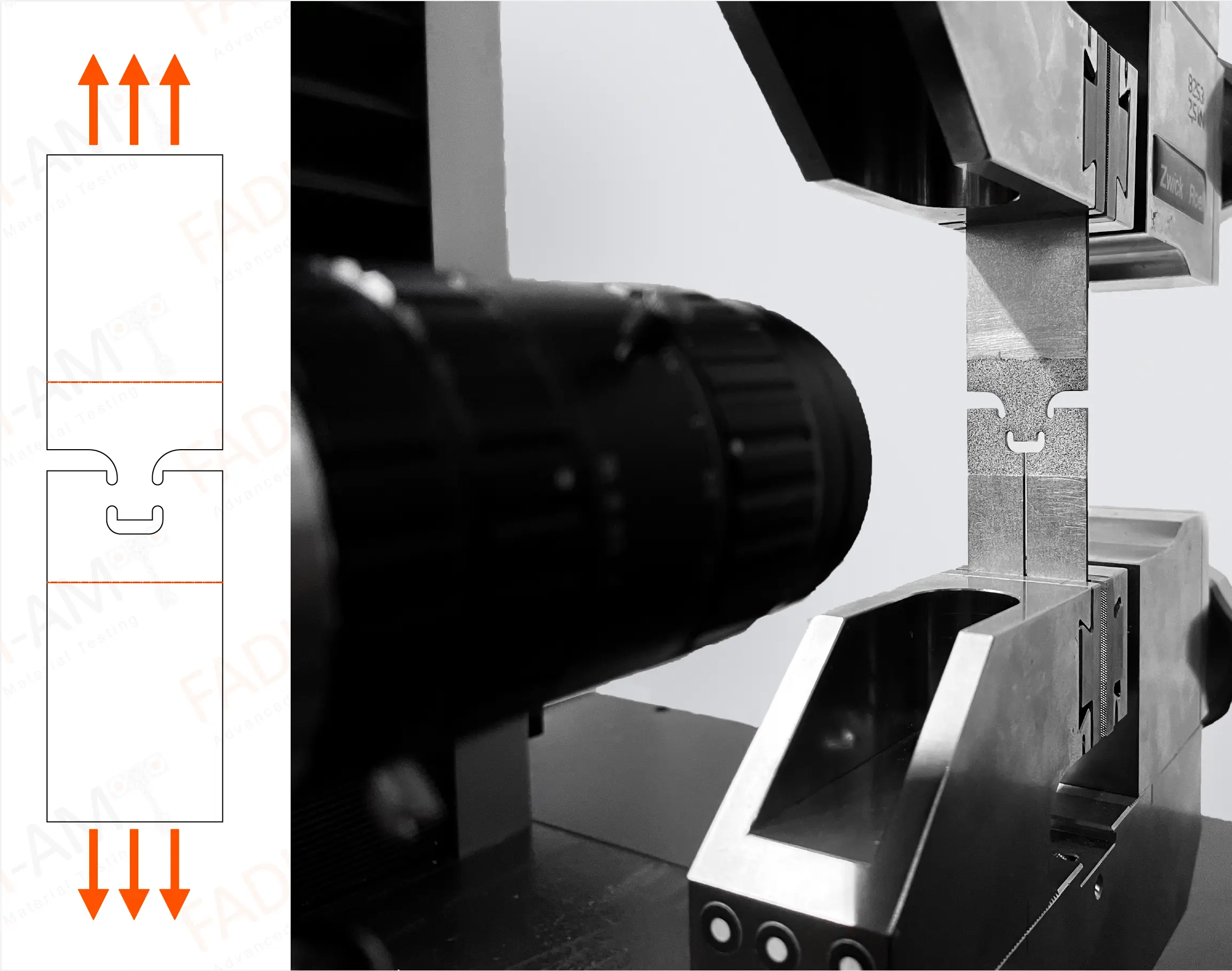

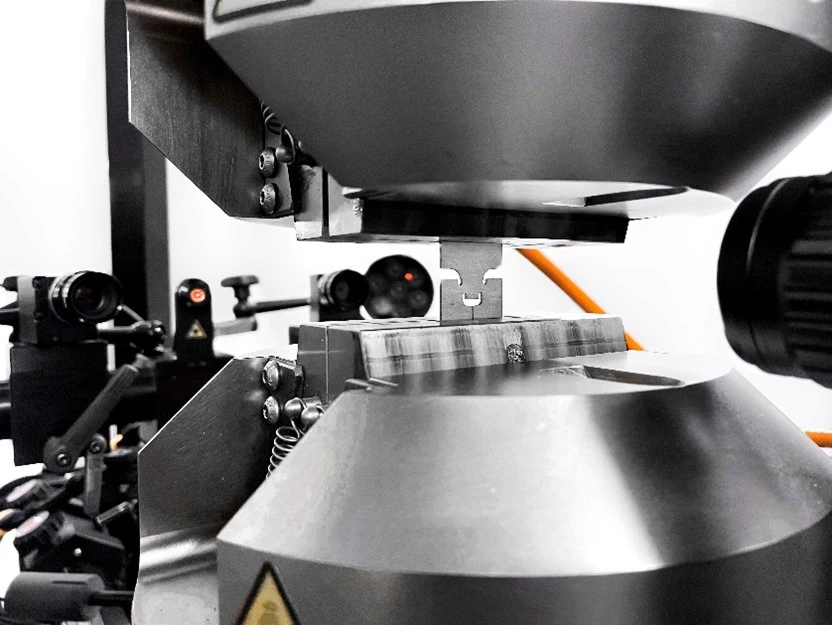

The objective of shear testing is to deform a material under shear

loading until fracture. Like most material tests, shear testing

takes stress and strain as quantities of interest.

Efficient shear testing methods tend to exploit techniques used in

other more common testing methods. For example, rather than

performing shear tests with a dedicated machine, shear testing is

usually designed to be compatible with the universal testing

machines (UTM) used in tensile testing. The key is to realize that

sample loading can be controlled by changing the sample geometry

rather than the external equipment. This allows shear testing to

use the same equipment setup as the uniaxial tension test.

The primary piece of equipment is the universal tester or pull

tester. This machine is oriented vertically, with two grips to

hold the material test sample at both ends. The bottom grip is

static, while the top grip moves upward during the test, anchored

by the crosshead. The crosshead is a beam that can only move up or

down; the speed of a test can be expressed by referring to the

“crosshead speed.” Crosshead movement is tightly controlled by the

machine's drive system, which in turn is controlled by electronics

and dedicated test control software. The control software

typically directs the crosshead to move upward at a constant

speed, though other control methods such as strain rate control

can be used.

With shear testing, it is very important to align the test sample

vertically. This is because a small tilt in the sample orientation

can cause large differences in loading within the material.

Universal testing machines often provide built-in apparatus for

ensuring a proper sample orientation, such as markings for reference

or adjustable bumpers to brace the sample against.

Sensors are also crucial for any material test. Like the standard

tensile test, shear testing can utilize load cells and

extensometers to give forces and strains. However, traditional

extensometers cannot provide comprehensive strain information for

a shear test. This is because common physical strain sensors are

unidirectional (they only measure strain in one direction) and

only one sensor can be placed in each location on the material.

This makes it impractical to measure shear strain, which acts in

two directions at points in very close proximity to each other.

One can use special strain gages for shear loading, but that is

highly time consuming, and still has many practical measurement

limitations. Instead, strain information is best provided using

digital image correlation (DIC). For DIC, the test piece is

painted in a speckle pattern and the entire test is filmed using

one or more cameras. The DIC software can compare the later images

to the initial “reference” image and calculate the displacement

(and thus, the strain) over the painted surface.

Shear Test Sample Geometry

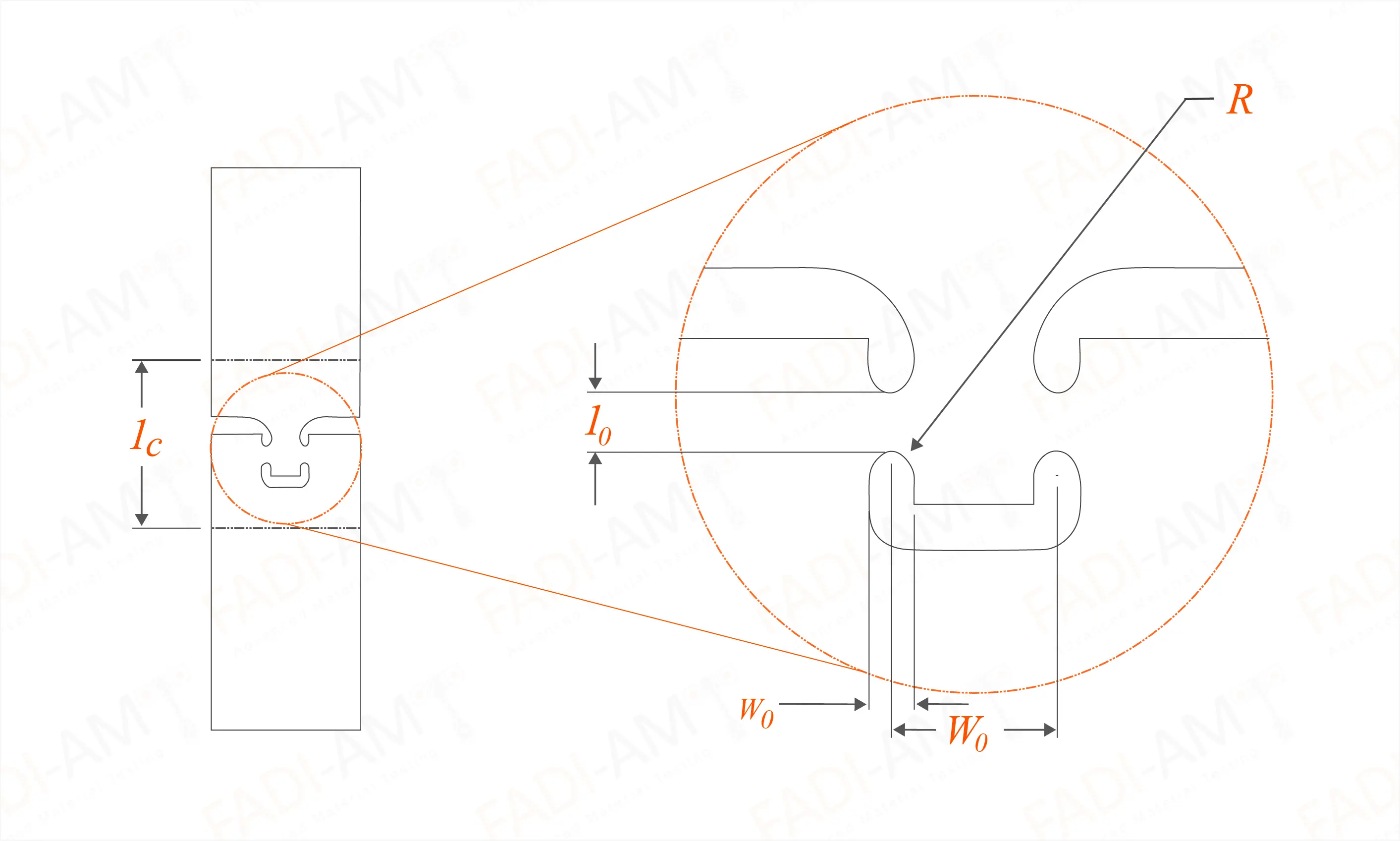

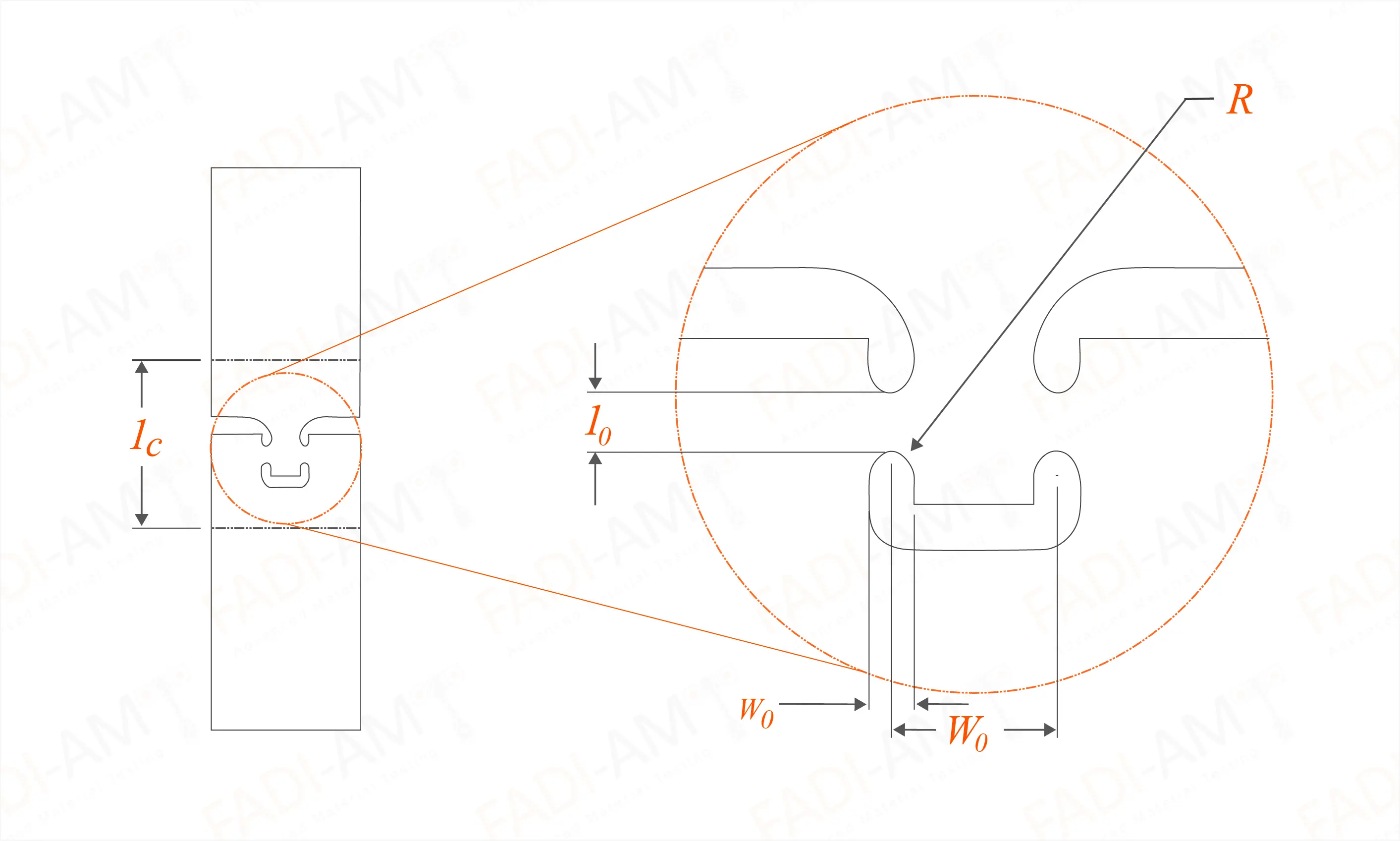

Shear testing requires a complex sample design compared to other

forms of pull testing. Because the objective is to fracture the

sample with a shear load, the sample is designed so that the

expected failure area is oriented perpendicular to the axis of the

testing machine.

Shear Sample Geometry

Because shear sample geometry is so intricate, several difficulties

arise when preparing and testing shear samples. Sample cutting can

only be done by sufficiently precise cutting methods, such as wire

electric discharge machining (Wire EDM); other methods such as

waterjet cutting and milling can be used but make it difficult to

create shear samples within an acceptable tolerance!

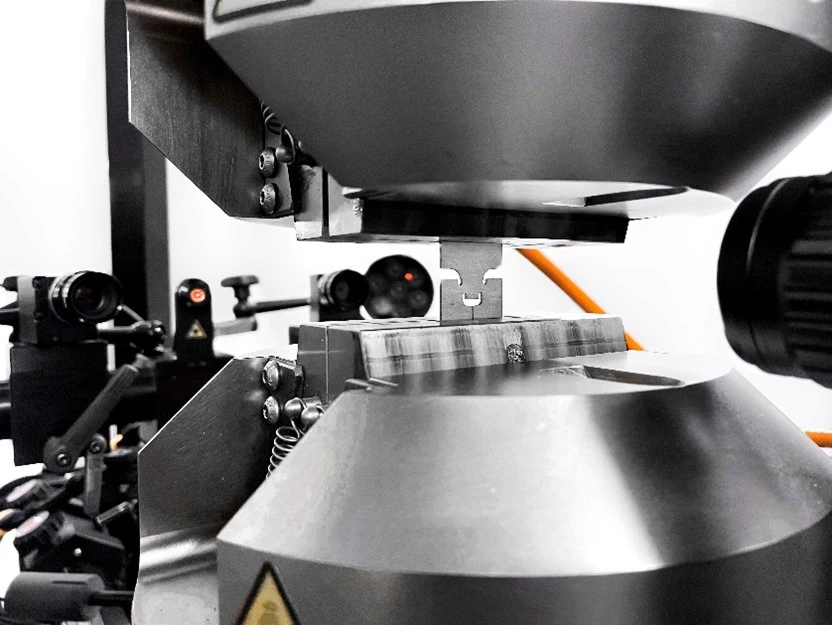

Shear Testing Method

The video below shows the Shear Testing method

Shear Testing Results

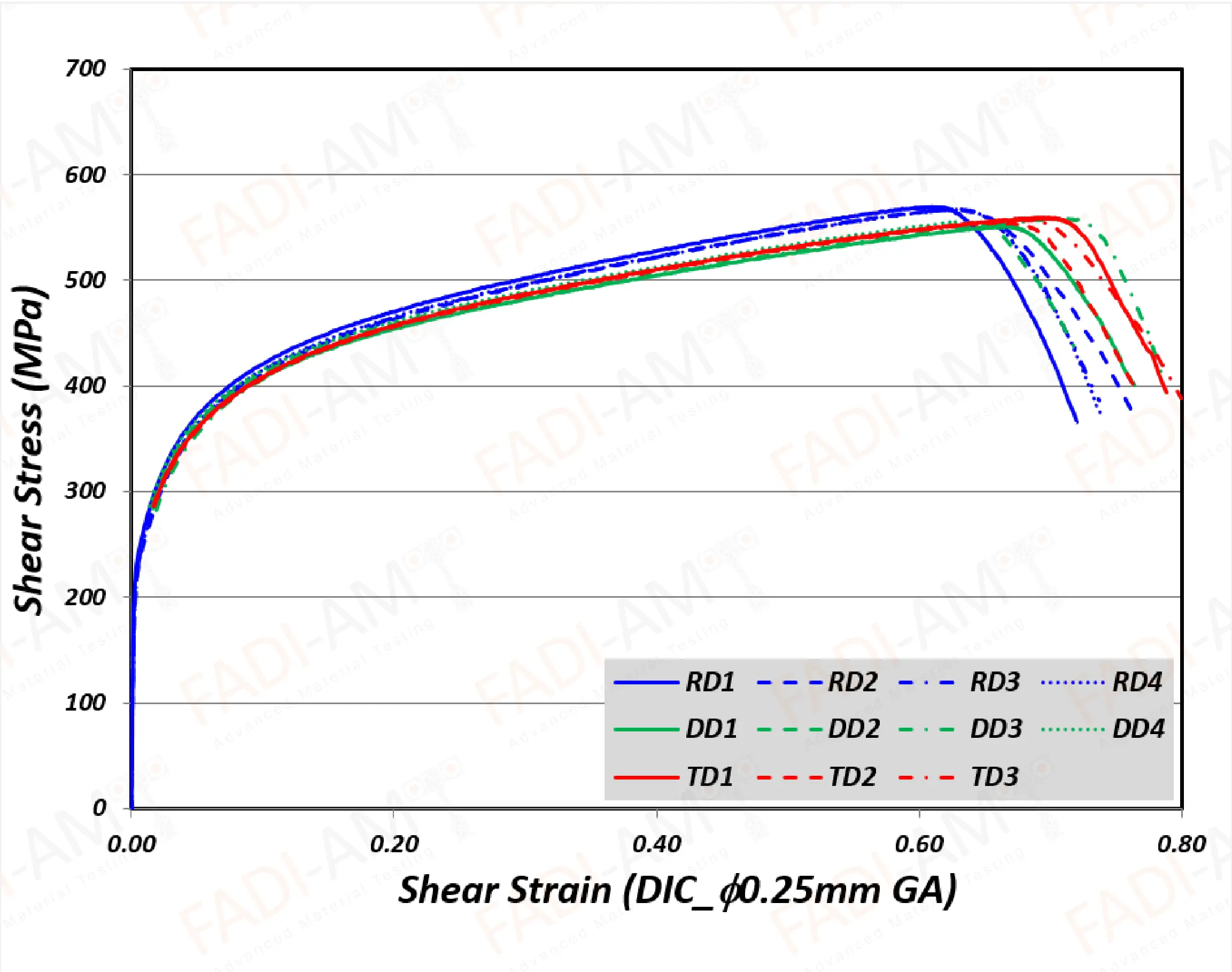

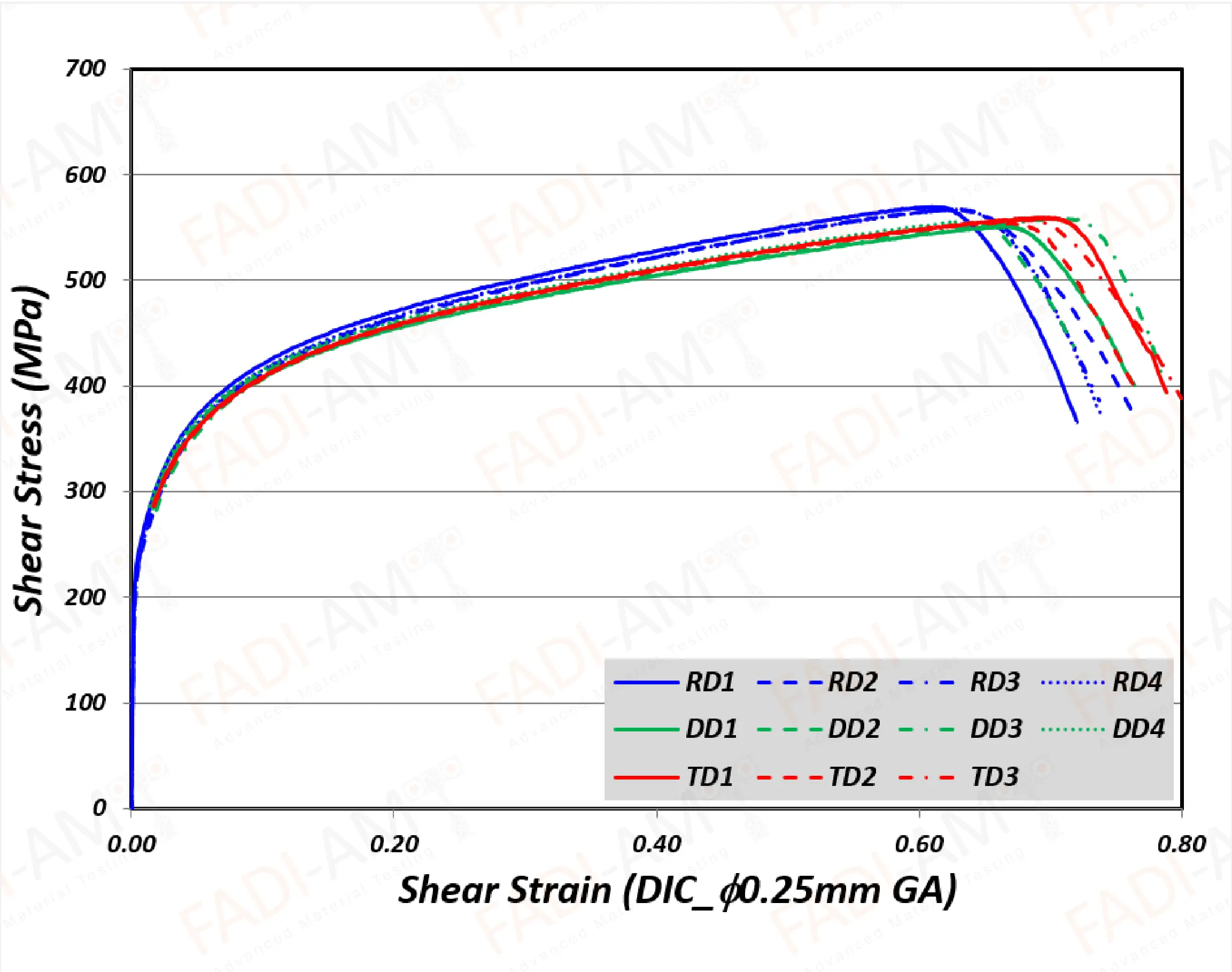

Using data from the test sensors, a shear stress strain curve can be

determined for the material. Like the more common tensile

stress-strain curve, the shear curve plots the stress in the

material at every time during the test against the measured strain

at that time. However, stress-strain curves derived from shear

conditions will look very different from those derived from uniaxial

loading, even for the same material. Knowledge of the relevant shear

stress-strain curves can be very useful when engineers work with

materials that are expected to undergo strong shearing conditions.

Shear Testing Results-Stress Strain Curves

Shear Testing Standards

Though standards such as ISO 4587, ISO 898, ASTM D1002, and ASTM

F606 cover shear testing for components and part interfaces,

international standards do not currently exist covering shear

testing for metal material samples.